-

Product Description

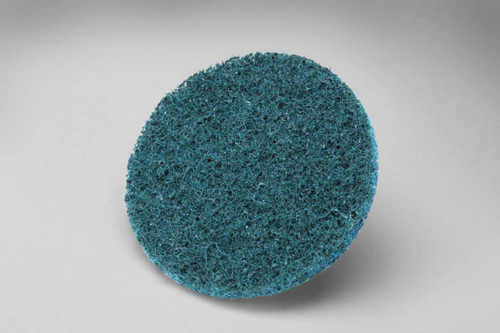

- AVAILABLE IN A RANGE OF GRADES: Choose from Super Fine (SFN), Very Fine (VFN), Medium (MED) and Coarse (CRS) to fit your application needs

- CHOOSE YOUR MINERAL: Super Fine grade is powered by super-sharp silicon carbide that excels in low-pressure and fine finishing applications, while all other grades feature harder and more durable aluminum oxide

- CONFORMABLE NONWOVEN WEB: Springy nonwoven fibers resist loading and conform to irregular or contoured surfaces

- GREAT FOR LOW-MEDIUM PRESSURE: Built for consistency in blending, cleaning, deburring, finishing, grinding, polishing, radiusing, refining and surface preparation

- QUICK AND EASY ATTACHMENT: Hook and loop backing makes for easy disc attachment, removal and re-attachment

- WORKS ON A RANGE OF METALS: Great for use on aluminum, mild steel, nickel alloy, stainless steel and titanium

The open-web material runs cool and resists loading to enable prolonged operation while evenly distributed aluminum oxide abrasives produce a high cut-rate for consistent finishing.

Our Scotch-Brite™ Surface Conditioning Disc uses aluminum oxide abrasive. Aluminum oxide is a popular choice among industrial professionals because of its cut-rate and long life. This mineral is a tough, durable abrasive that self-fractures to expose fresh cutting edges in use, whereas traditional abrasives, such as garnet, quickly wear down with use. Due to its high cut-rate, hardness, strength, and low heat retention, aluminum oxide mineral is widely used in grinding applications in addition to sanding and finishing use. Aluminum oxide is suitable on a wide variety of substrates in both woodworking and metalworking, including ferrous alloys.

Our Scotch-Brite™ industrial abrasives are unique surface conditioning products with abrasives incorporated into non-woven nylon or synthetic fibers. Combining abrasives with the fibers creates an abrasive system that delivers consistent results for the life of the product. The open-web material runs cool and is load resistant, which keeps the abrasive minerals cutting at high performance by limiting clogging of the fibers.

Scotch-Brite Brand Quality

The Scotch-Brite Surface Conditioning Disc, model SC-DH, is designed for reliable surface preparation. This brand is known for durable, non-woven fiber construction that conforms well to irregular or contoured surfaces without damaging the base material.

With the SC-DH model, you get a product that balances toughness and flexibility, making it ideal for cleaning, blending, deburring, and finishing tasks. The brand’s reputation ensures consistent performance across various applications.

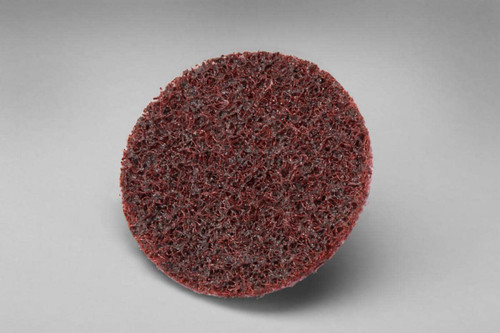

Coarse Grade Performance

This Surface Conditioning Disc comes in the A/O Coarse grade, which features aluminum oxide abrasives. This grade is perfect for low to medium pressure applications, providing a high cut-rate and long-lasting abrasive life.

The coarse grade excels in tasks like grinding, polishing, and surface preparation. Its aluminum oxide mineral self-fractures to expose fresh cutting edges, maintaining efficiency throughout use.

Disc Size And Format

The disc measures 2 inches in diameter and uses a NH (non-hex) backing format. This size is compact enough for detailed work while still providing effective surface conditioning.

The hook and loop backing system allows for quick and easy attachment, removal, and re-attachment. This format supports efficient workflow and reduces downtime during disc changes.

Pack Count Convenience

This product is sold in packs of 50 discs per bag, with 200 discs per case. Such quantities are ideal for industrial or professional settings where frequent disc replacement is necessary.

Having a large pack count ensures you have enough discs on hand for extended projects, reducing the need for frequent reordering and helping maintain productivity.

Versatile Surface Applications

The SC-DH disc works well on a variety of metals including aluminum, mild steel, nickel alloy, stainless steel, and titanium. This versatility makes it suitable for many metalworking tasks.

Its conformable nonwoven web resists loading and adapts to contoured surfaces, ensuring consistent results on different materials without undercutting or damaging the base.

Scotch-Brite Surface Conditioning Disc, SC-DH, A/O Coarse, 2 in x NH, 50/Bag, Case of 200

Scotch-Brite

$244.42 Per Case